In the dynamic landscape of the metalworking industry, Punjab stands out as a region renowned for its rapid industrialization and flourishing manufacturing sector. As demand for high-quality metal products continues to rise, the significance of precision and accuracy in metal fabrication cannot be understated.

Among the various tools and technologies employed by manufacturers in Punjab, straightening machines play a pivotal role in ensuring that metal bars, tubes, and profiles meet stringent industry standards.

In this comprehensive blog, we will delve deeper into the significance of straightening machines in Punjab metalworking sector, explore their different types, understand their working principles, and analyze the numerous benefits they offer to manufacturers.

Importance of Straightening Machines Punjab’s Metalworking Industry:

As the metalworking industry in Punjab continues to thrive, manufacturers face increasing pressure to produce high-quality products within tight tolerances. This is where straightening machines become indispensable. Distortions and imperfections can occur during the metal manufacturing process due to various factors like rolling, cutting, or welding. These distortions can compromise the mechanical properties and structural integrity of the metal, making it imperative to rectify them before the final product reaches the market.

Straightening machines in Punjab have emerged as a solution to this challenge, enabling manufacturers to achieve precise dimensions, eliminate distortions, and deliver products that adhere to exact specifications. With a focus on quality and precision, Punjab’s metal fabricators can not only meet the demands of local industries but also compete in national and international markets.

Types of Straightening Machines:

In the diverse landscape of metal fabrication, different types of straightening machines cater to specific needs and materials:

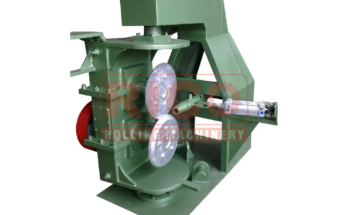

a) Roll-type Straightening Machines: These machines feature multiple rollers that apply pressure on the metal workpiece, causing it to bend in the opposite direction of its existing distortion. Roll-type straighteners are commonly used for long metal bars and tubes that require uniform straightness.

b) Stretching-type Straightening Machines: Employing a unique principle, stretching-type machines stretch the metal workpiece beyond its elastic limit and then release it. This process helps in eliminating plastic deformations, thus straightening the material effectively.

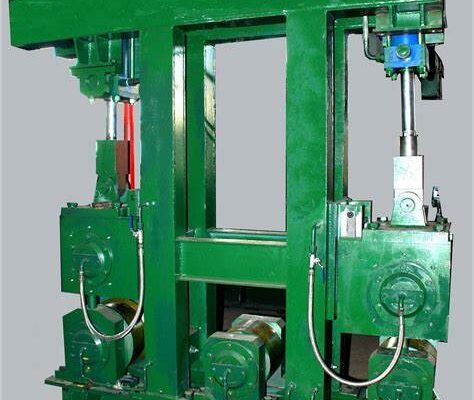

c) Press-type Straightening Machines: Press straighteners use hydraulic or mechanical force to adjust the shape of metal products. They are particularly suitable for thicker and heavier profiles that require substantial force for straightening.

Working Principles of Straightening Machines:

a) Feeding the Workpiece: The metal workpiece is fed into the straightening machine, where it is positioned between the sets of rollers or pressing elements, ready to undergo the straightening process.

b) Applying Pressure: The machine’s rollers or pressing elements exert pressure on the workpiece at specific points, carefully manipulating its shape to bring it back to its original form or desired straightness.

c) Sequential Straightening: In the case of multi-roll straightening machines, the workpiece passes through multiple sets of rollers in a carefully choreographed sequence. Each set makes slight adjustments to the alignment, continuously refining the straightness until the desired precision is achieved.

Benefits of Using Straightening Machines Punjab:

The incorporation of straightening machines into the metalworking process offers a plethora of advantages for manufacturers in Punjab:

a) Enhanced Quality: Straightening machines play a vital role in maintaining product quality by rectifying distortions and ensuring that metal components adhere to precise dimensional tolerances. High-quality products lead to improved customer satisfaction and brand reputation.

b) Reduced Material Waste: By salvaging distorted metal pieces, straightening machines significantly reduce material waste. This not only contributes to cost-efficiency but also aligns with sustainable manufacturing practices, making them an eco-friendly choice.

c) Increased Productivity: Straightening machines streamline the production process, enabling manufacturers to achieve higher output rates and quicker turnaround times. With quicker processing times, businesses can take on larger orders and meet tight deadlines.

Also Read: Future of Automotive & Transportation – What Electric Vehicles Hold For Us

Wrapping up

In conclusion, BS Mechanical stands as a prominent and reputable company specializing in the sale of straightening machines Punjab. Our commitment to providing high-quality industrial machinery and metalworking solutions has earned us a strong reputation in the region’s manufacturing sector.

By choosing BS Mechanical as your trusted supplier of Straightening Machines, you gain access to top-of-the-line equipment designed to achieve precise and accurate results in metal fabrication. Our machines are carefully crafted with advanced technology and engineering expertise to meet the demanding requirements of the metalworking industry in Punjab.